TECHNOLOGY

Find out how you too can discover the knife's maximum potential with SHARPX today.

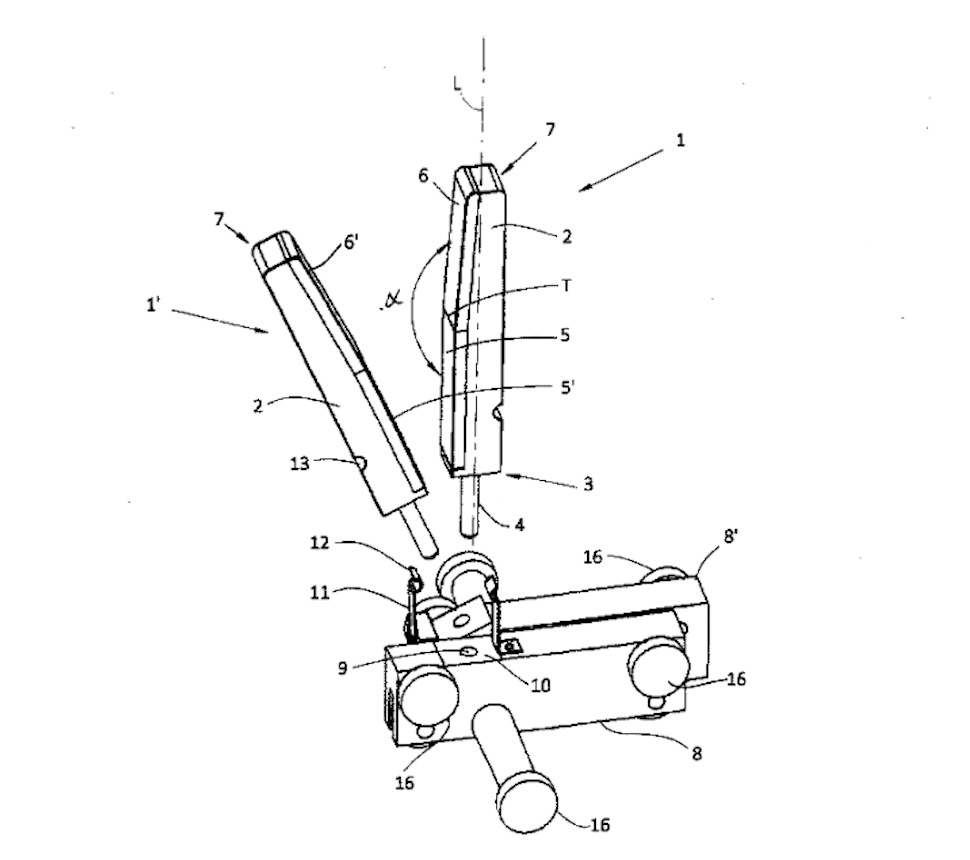

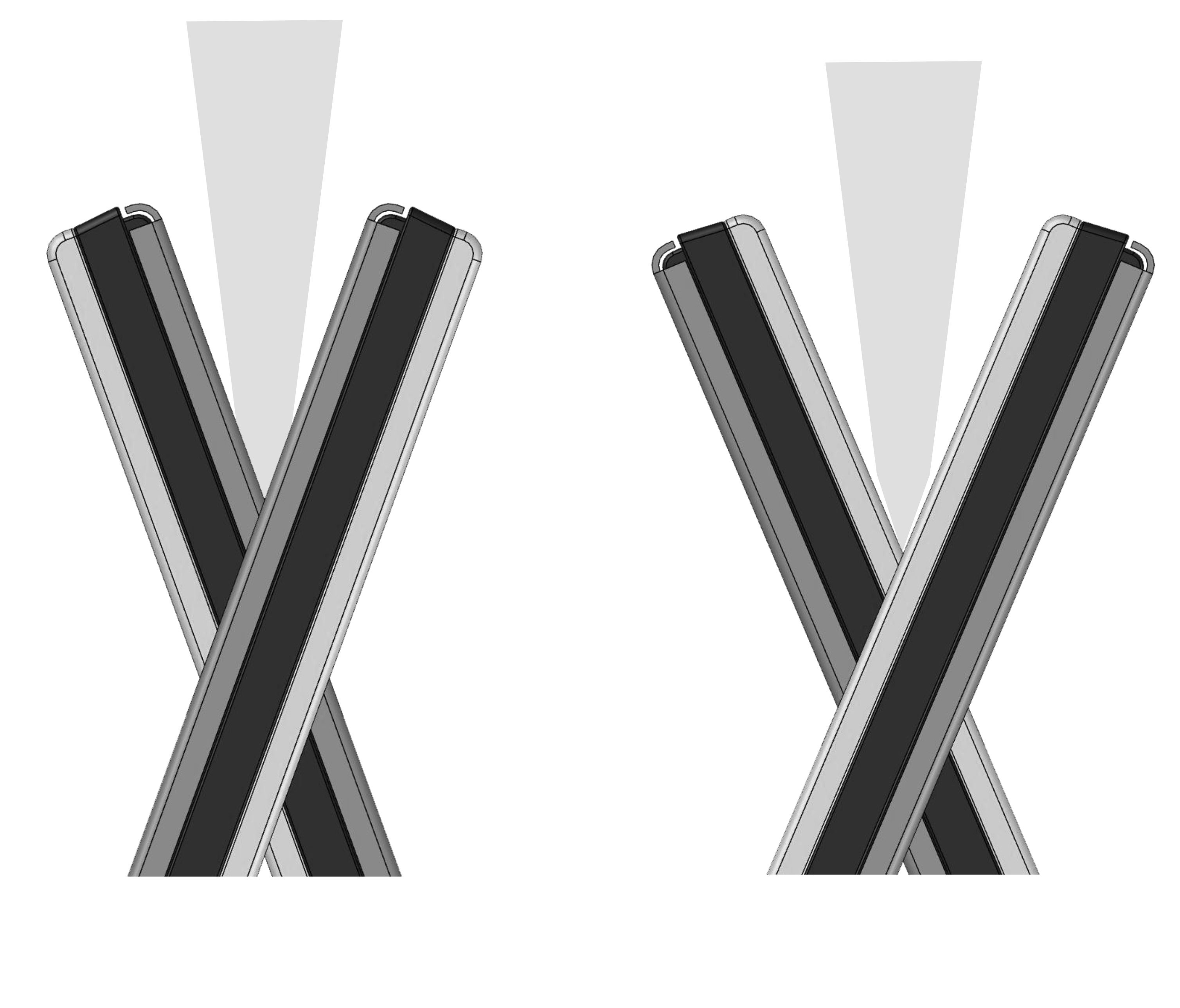

Swedish patented technology

Professional result

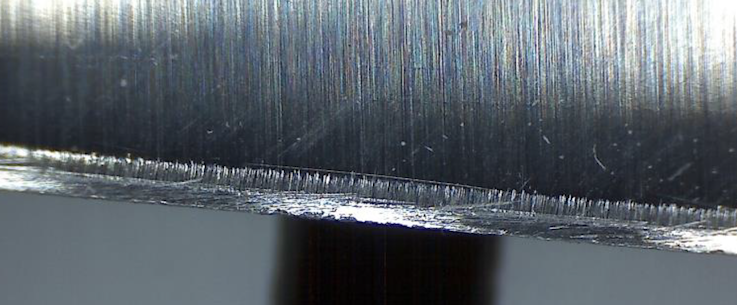

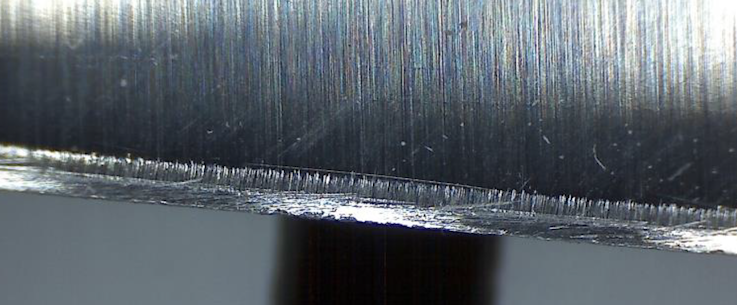

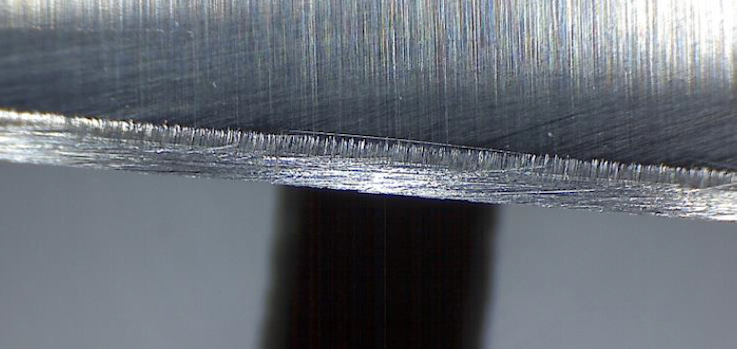

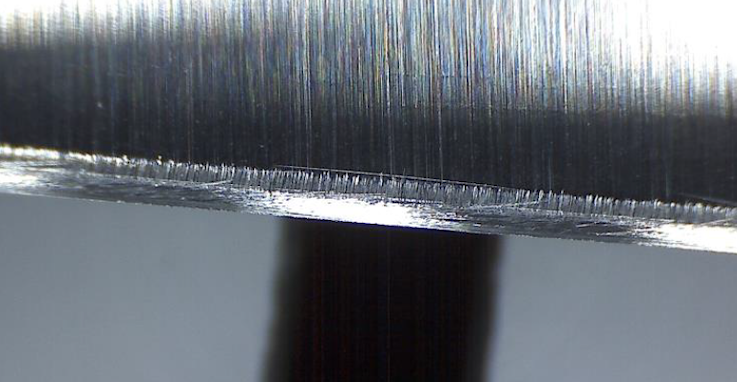

Sharpening process in microscope

After Diamond grinding

After Ceramic polishing

Two-step sharpening process

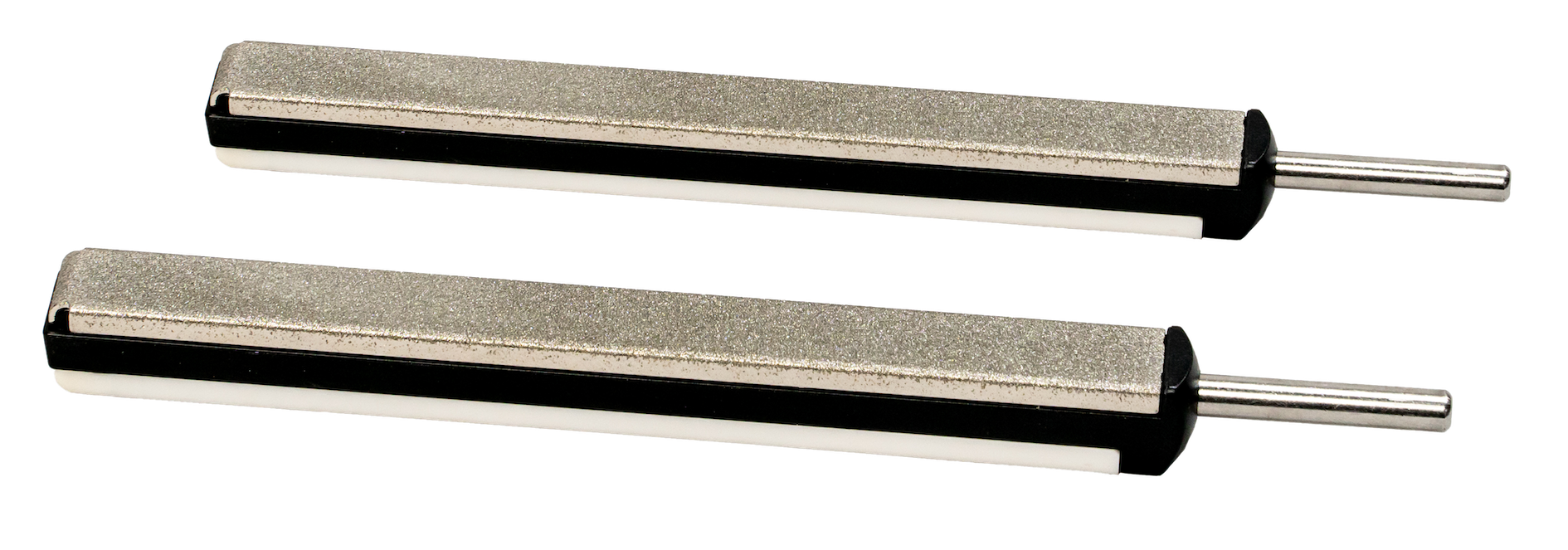

Combined premium rods

Quality